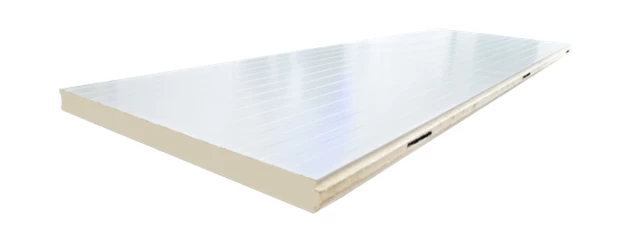

100mm cold room panels

100mm cold room panels represent a highly efficient solution for constructing controlled temperature environments essential in various industries like food processing, pharmaceuticals, and agriculture. These panels, measuring 100mm in thickness, provide exceptional insulation, ensuring a consistent and reliable cold environment ideal for preserving perishable goods.

İnsulated cold room panels

Insulated cold room panels are specialized construction materials used for creating temperature-controlled environments, like refrigerators, freezers, and cold storage facilities. These panels are designed to maintain a consistent temperature within the room, which is crucial for preserving perishable goods like food, pharmaceuticals, and other temperature-sensitive products. Here are some key aspects of insulated cold room panels:

- Material: They are typically made of metal sheets with an insulating core. The core is usually made of polyurethane (PU), polyisocyanurate (PIR), or expanded polystyrene (EPS), known for their excellent insulation properties.

- Thermal Insulation: The primary function of these panels is to provide thermal insulation. They prevent the transfer of heat into or out of the cold room, maintaining the desired temperature with minimal energy consumption.

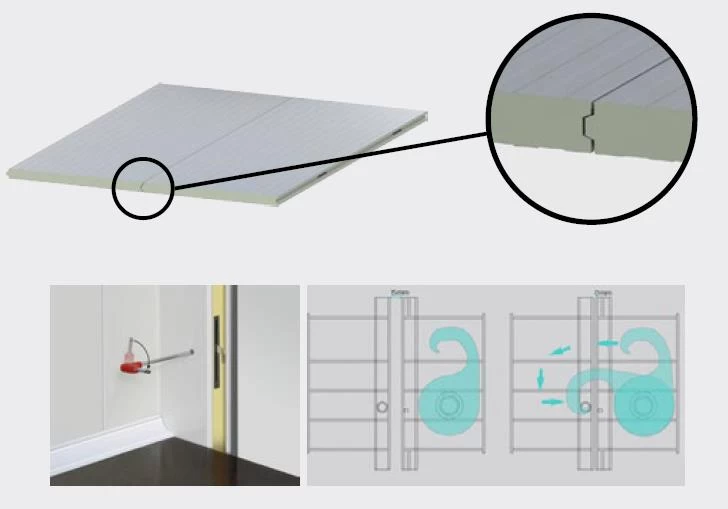

- Airtight Seal: The panels are designed to fit together seamlessly, creating an airtight seal that prevents air leakage. This is crucial for maintaining temperature and humidity levels inside the cold room.

- Durability and Moisture Resistance: Given the environment in which they are used, these panels are also resistant to moisture and corrosion, which helps in maintaining hygiene and prolonging the life of the cold room.

- Ease of Installation: They are often designed for easy and quick assembly, which is beneficial for constructing cold storage facilities within a short time frame.

- Customization: Insulated cold room panels can be customized in terms of size, thickness, and finishes to meet specific requirements of different cold storage applications.

- Energy Efficiency: By providing excellent insulation, these panels help in reducing the energy consumption of cooling systems, making them more efficient and cost-effective in the long run.

- Fire Resistance: Some insulated panels also offer fire resistance, which is an important safety feature.

Buy Cold Room Panels

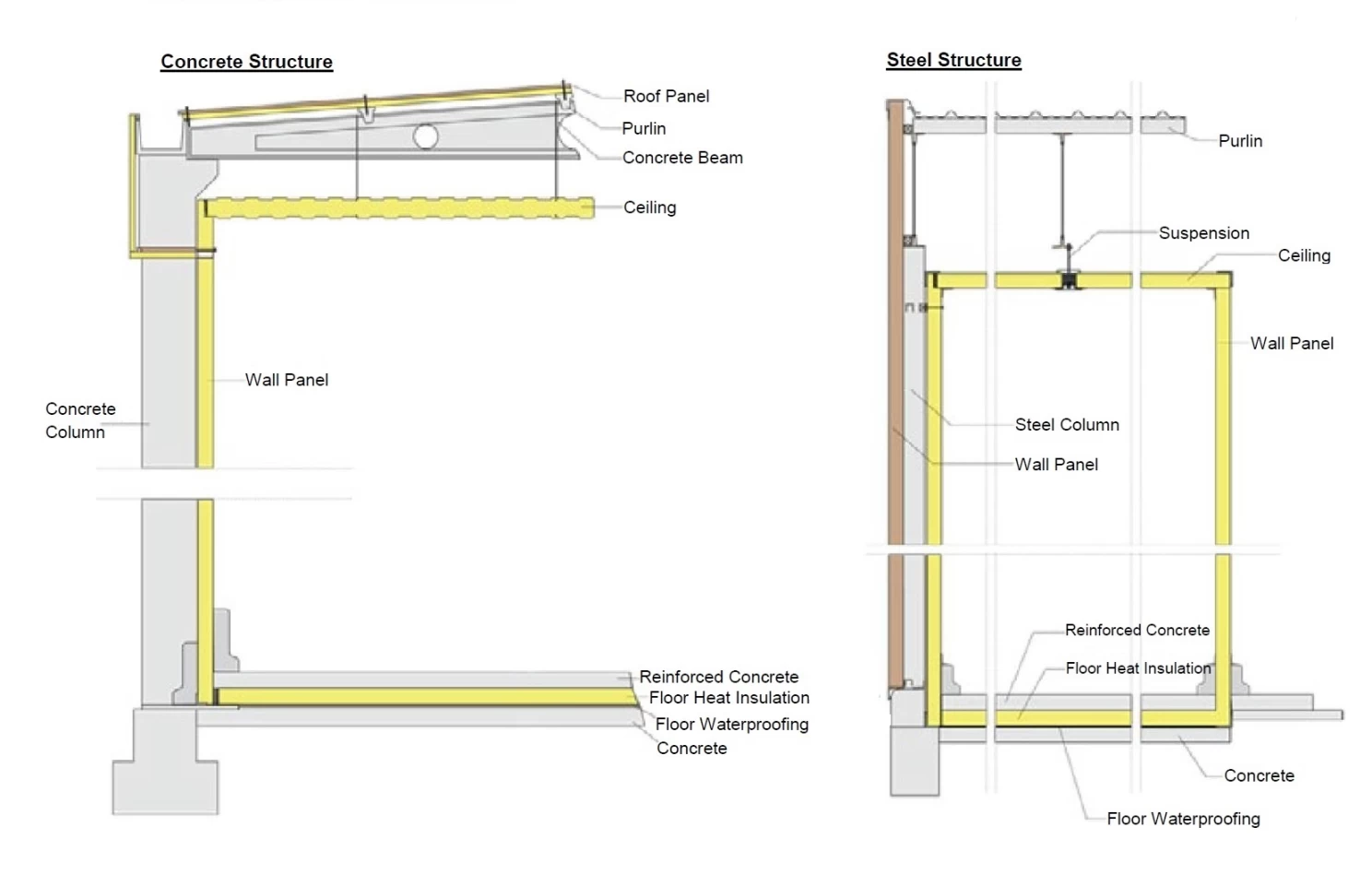

Tamcold offers a range of insulated panels that are essential for creating effective cold storage environments. These panels are integral in isolating cold rooms from external conditions and are manufactured to meet international standards.

Key features of Tamcold cold room panels include

- Variety in Thickness: Tamcold produces panels in various thicknesses such as 60 mm, 80 mm, 100 mm, 120 mm, 150 mm, and 200 mm.

- Material Quality: The panels consist of B1 FIRE SAFE CLASS certified, CFC-free polyurethane with a density of 42 kg/m³. This is injected at high pressure between two polyester-coated galvanized steel sheets of 0.50 mm thickness.

- Design and Functionality: They are designed with male and female formats ensuring perfect joining and interlock with a specially designed eccentric locking system. This system makes the panels easy to assemble and disassemble without damaging their structure.

- Customizable Dimensions: Panels are available in 116 cm width and can be manufactured to any desired length up to 13.5 meters.

- Surface Variations: For wall and ceiling panels, they use polyester painted galvanized steel sheet (RAL 9002), with options for PVC coated or Cr-Ni (AISI 304 stainless steel) sheets.

In terms of benefits, using Tamcold’s interlocking cold room panels provides advantages such as enhanced durability, energy savings, ease of cleaning, and hygienic qualities suitable for various applications including hospitals and grocery stores.

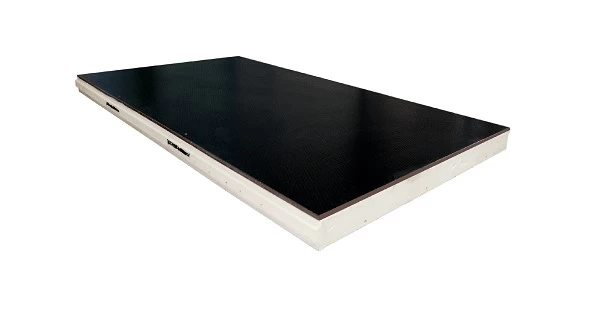

Cold Room Ceiling Panels

Cold room ceiling panels are a crucial component in the construction of temperature-controlled environments, such as cold storage facilities, freezers, and refrigeration rooms. These panels are specifically designed for use on ceilings to provide insulation and maintain the desired temperature within the enclosed space. Here are some key details about cold room ceiling panels:

- Insulation Material: Cold room ceiling panels are typically constructed with a core insulation material that has excellent thermal properties. Common insulation materials used include polyurethane (PU), polyisocyanurate (PIR), and expanded polystyrene (EPS). These materials help to prevent heat transfer and maintain a consistent temperature inside the cold room.

- Panel Thickness: The thickness of cold room ceiling panels can vary depending on the insulation requirements. Thicker panels generally offer better insulation properties and are suitable for environments where precise temperature control is essential.

- Airtight Seal: Just like wall panels, cold room ceiling panels are designed to fit together seamlessly, creating an airtight seal. This seal is crucial for preventing temperature fluctuations and ensuring the cold room operates efficiently.

- Durability: These panels are constructed to be durable and long-lasting, as they are exposed to cold temperatures and moisture. They are often made with corrosion-resistant materials to withstand the conditions of a cold storage environment.

- Customization: Cold room ceiling panels can be customized to meet specific size and design requirements. They can also come with various finishes and coatings, such as stainless steel or aluminum, to suit different applications.

- Fire Resistance: Depending on the manufacturer and specific requirements, some cold room ceiling panels may offer fire-resistant properties to enhance safety.

- Easy Installation: These panels are designed for easy and efficient installation on ceilings, helping to reduce construction time and costs.

- Energy Efficiency: By providing effective insulation, cold room ceiling panels contribute to energy efficiency, reducing the overall energy consumption of the cooling system.

Cold room ceiling panels play a crucial role in maintaining the integrity of temperature-sensitive products and ensuring the energy-efficient operation of cold storage facilities.