Container type cold storages are the most essential elements to maintain cold chain of the perishable products during transportation. Additionally, they are used for different areas like camping regions, power shortage regions, or special events where additional short-term cold storage is required a couple of days.

Container type refrigeration allows easy transportation to another place; you will have flexibility of just relocating in case of changing location of your premises.

Refrigerated containers are also preferred due to practical and ease of use. You just need to provide energy to operate the system and will obtain required cooling within an hour.

We design and manufacture right type of portable refrigerated containers that fully meet your requirements. We design container type refrigeration for different purpose of use such as cold storage, chilling room, freezing room or blast freezing. We offer custom made solutions according to your demand by installing proper refrigeration unit, interlocking panels and suitable doors. Container type cold rooms address needs of many industries to preserve wide range of products such as fresh fruits, meats, fish, ice cream, chicken, vaccinations, sensitive chemicals etc.

For special projects, special sizes can be produced outside of standard sizes.

20 Dc Container

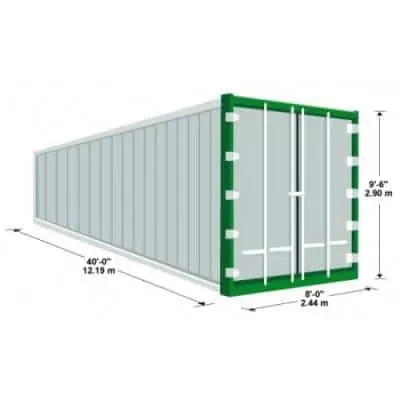

40 Hc Container

According to the place of use; containers can be designed for different temperatures

What is Container Type Cold Storage

TamCold Container Type Cold Storage: Installation and Construction